Enterprise Platforms

Application Development

Data & AI

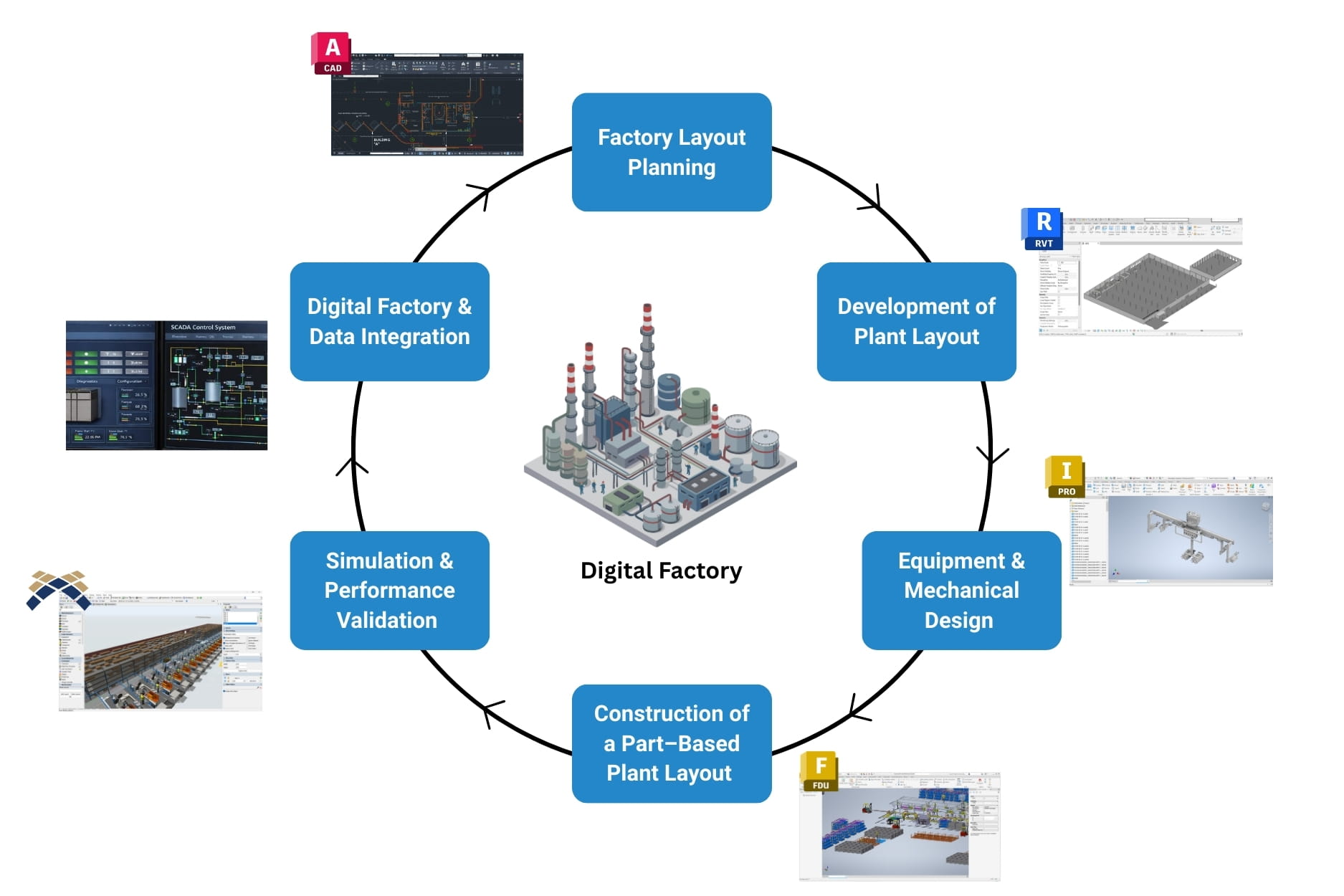

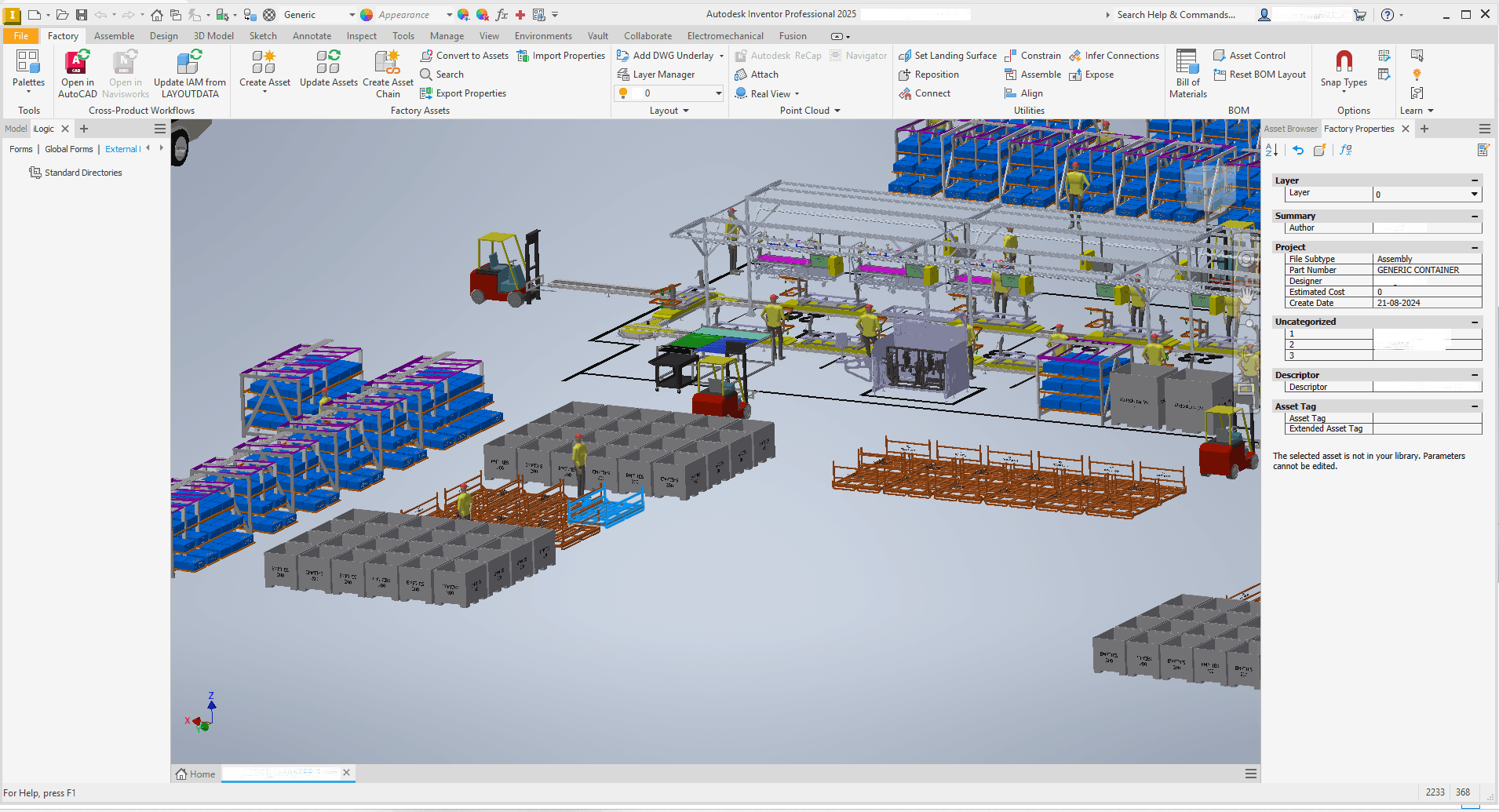

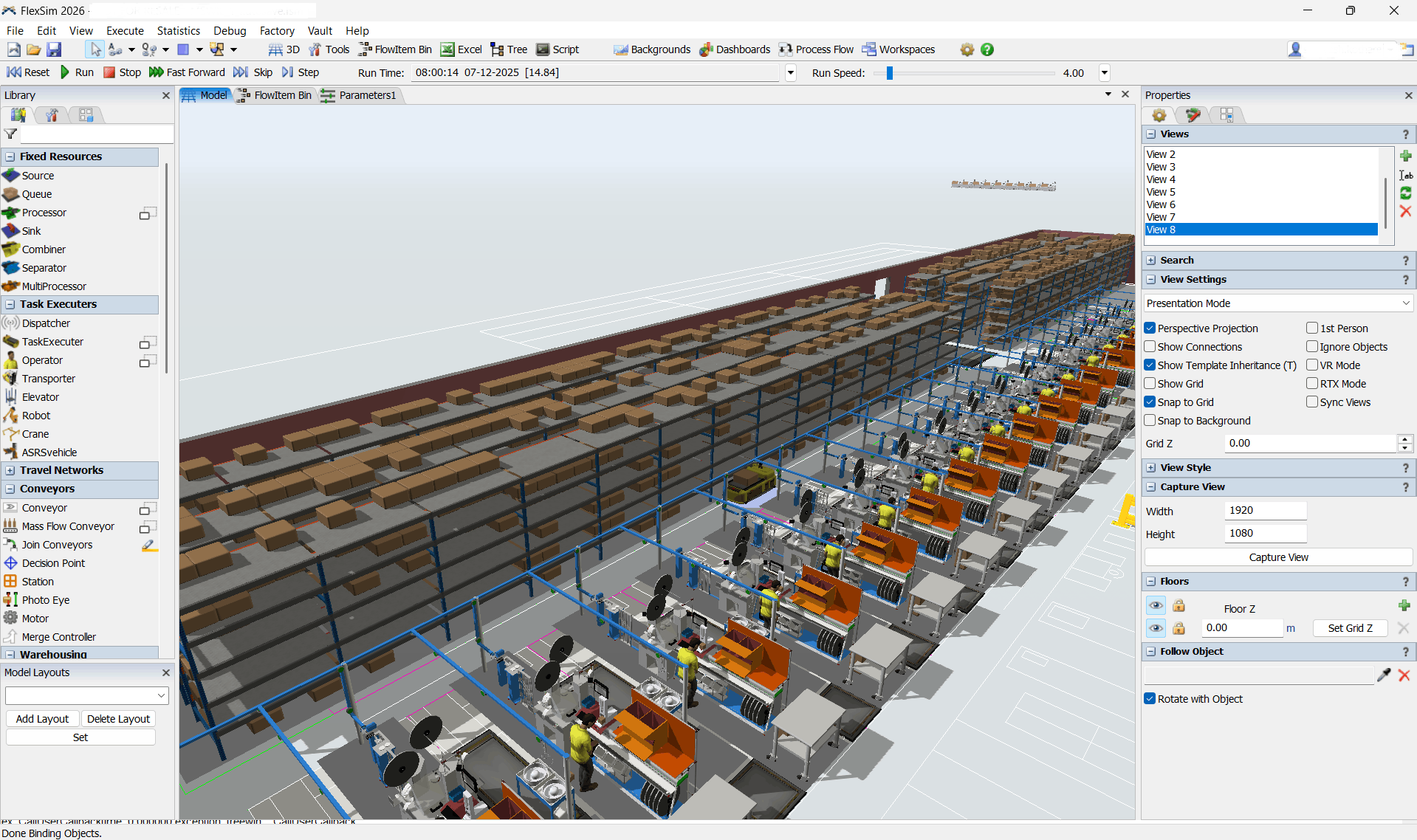

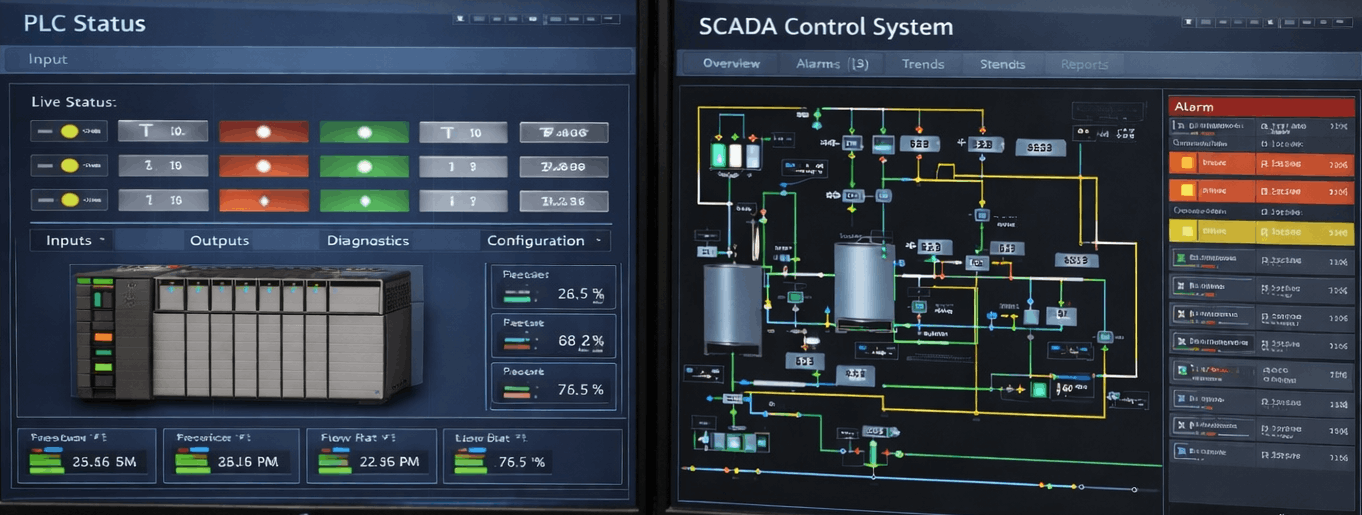

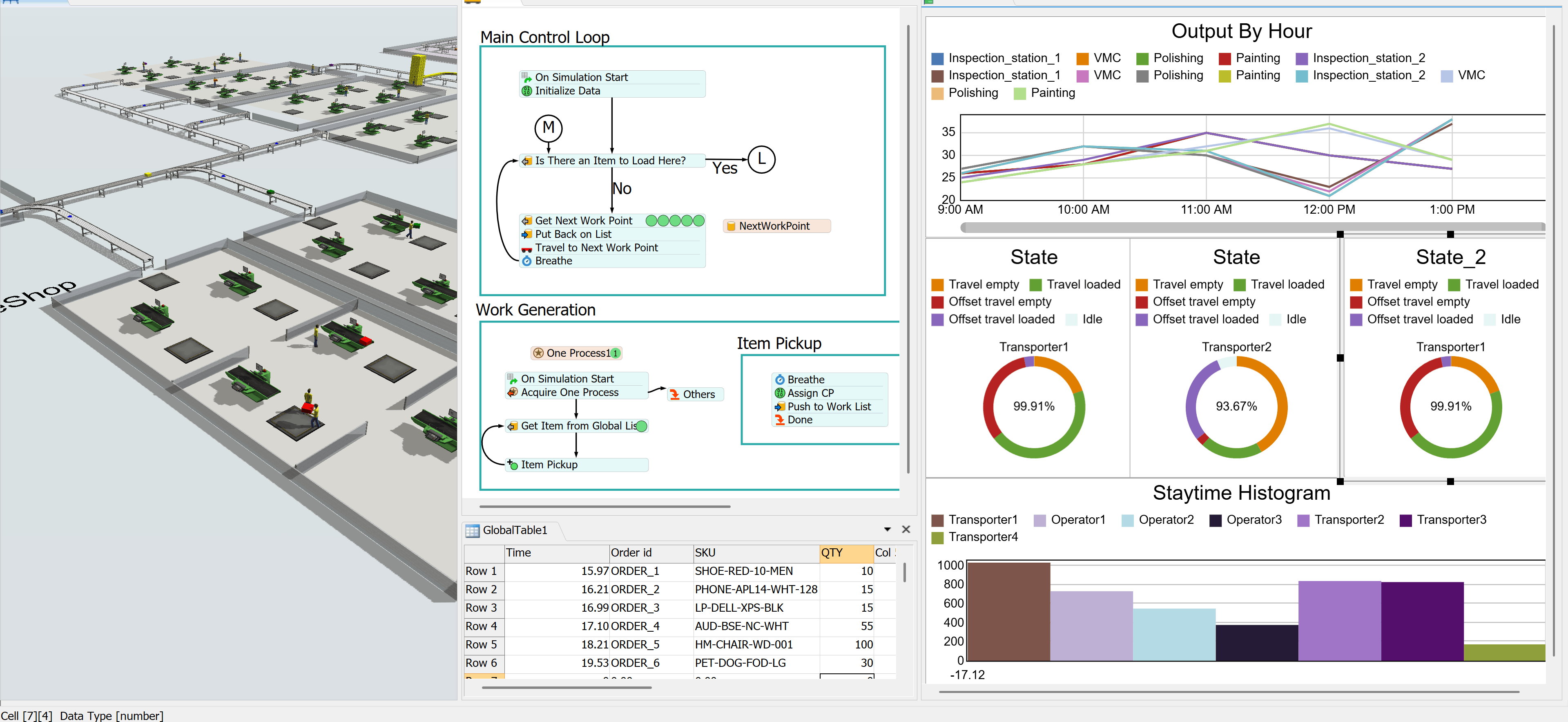

Digital Twin

Cloud

Solution Engineering

Extended Development Centre

ACC Integration with Enterprise Applications

Autodesk Fusion Manage PLM with ERP Integration

ACC Implementation Services

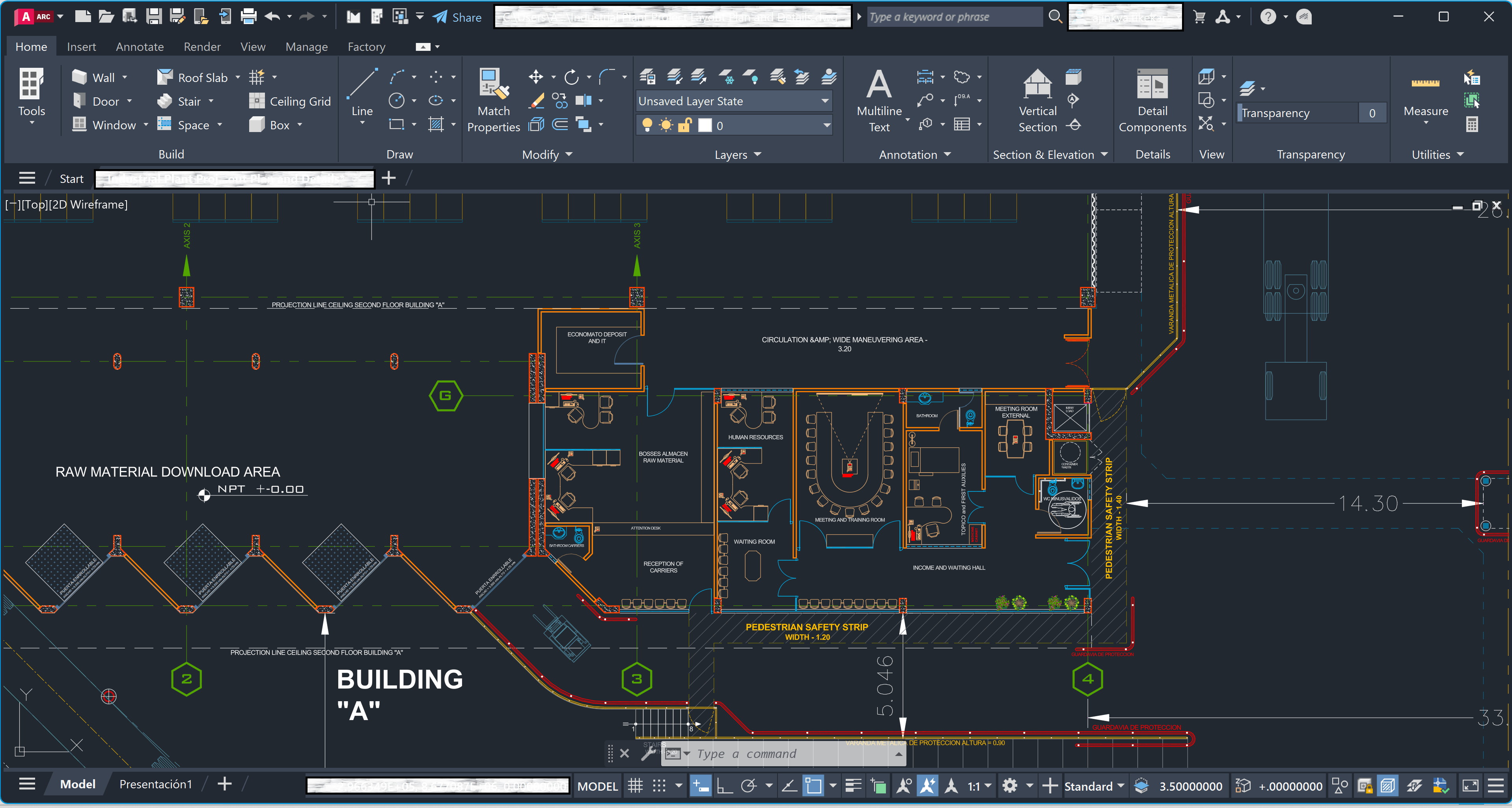

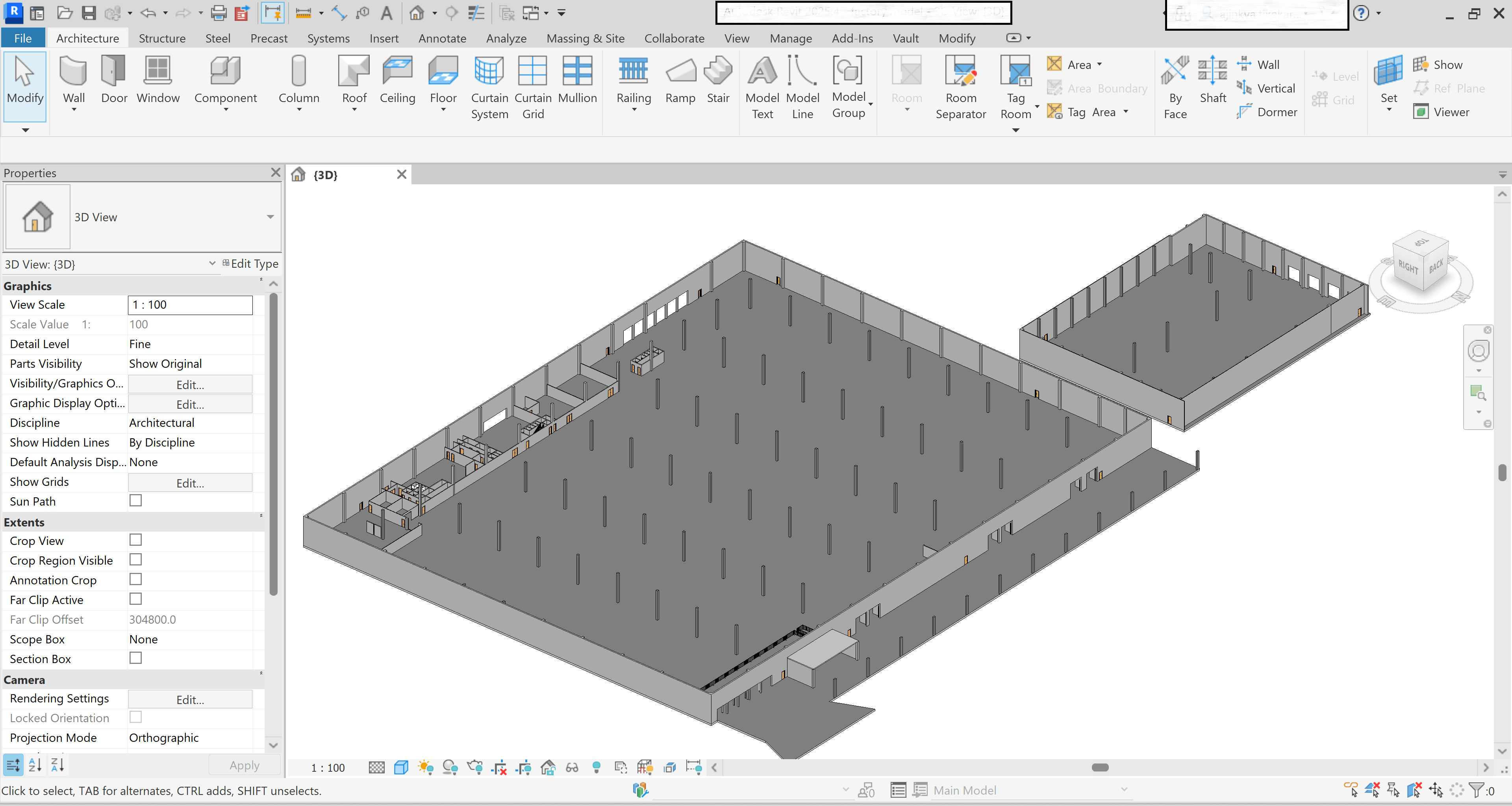

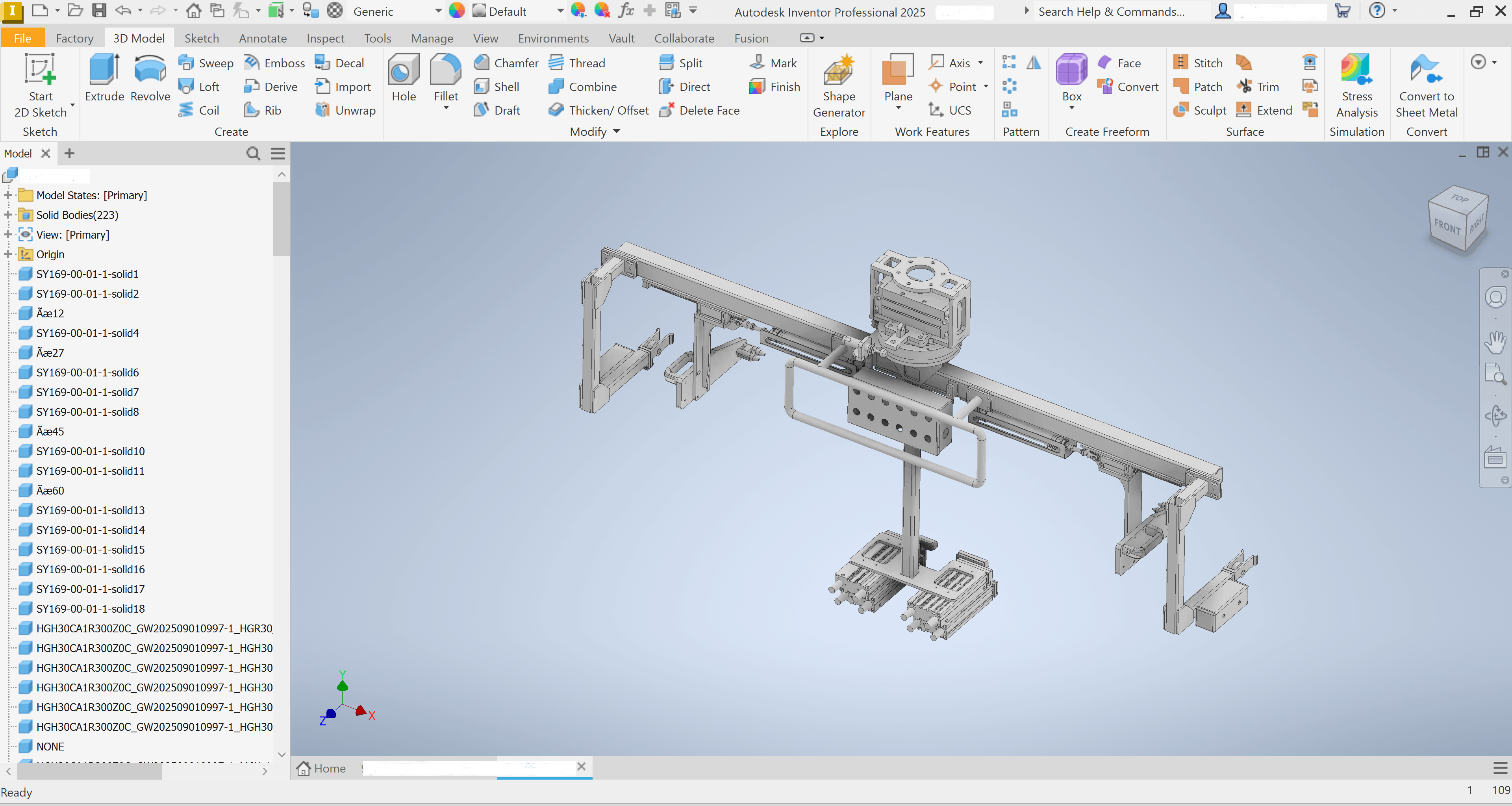

Design Automation for CAD & BIM Applications

Autodesk BIM 360 & Construction Cloud Migration Services

4D Schedule Visualization

5D Cost Visualization

View and explore what our research team is up to. Experience the depth and demonstration of live applications.